Proof-of-Concept Method Advances Bioprocess Engineering for a Smoother Transition to Biofuels

Japanese researchers propose green industrial strategy that employs bacterial cells to relay feedback and optimize production

Bioprocess engineering focuses on enhancing product yield. It also ensures high output rates and minimal utilization of raw materials. Such precise control is achieved by optimizing the biological behavior of microorganisms employed during the production process. Nevertheless, a process-model mismatch (PMM) emerges when a notable disparity arises between the projected and real production processes. A recent study showcases a proof-of-concept method for effectively addressing the issue of PMM.

One of the primary goals of bioprocess engineering is to increase the yield of the desired material while maintaining high production rates and low raw material utilization. This optimization is usually accomplished by controlling the behavior of microorganisms used in the process and ensuring that their biological capabilities are fully utilized. This control may be computerized (in silico feedforward) or autonomous (in-cell feedback) which predicts the optimization based on inputs received. However, a process-model mismatch (PMM) occurs when there is a discrepancy between the predicted and actual production processes.

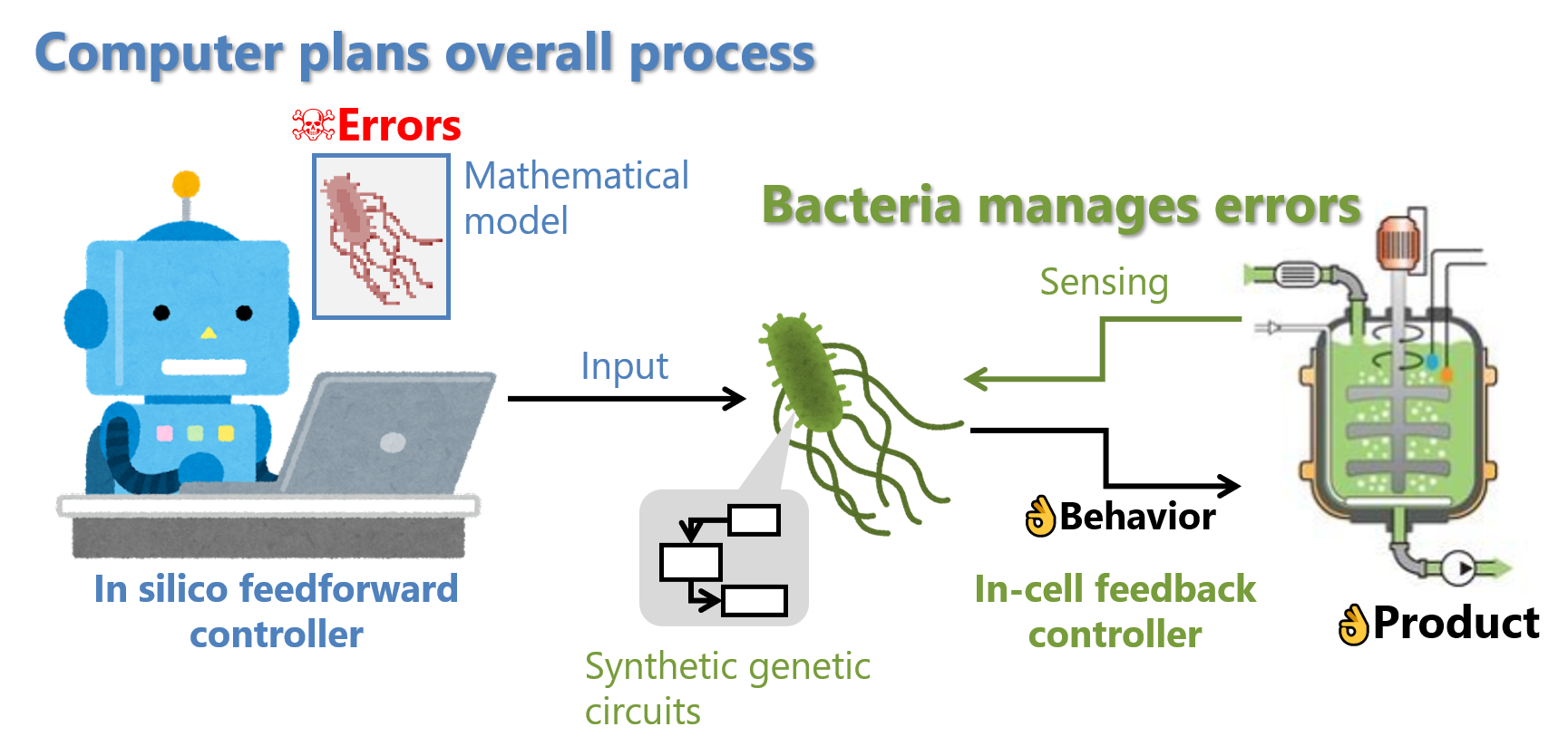

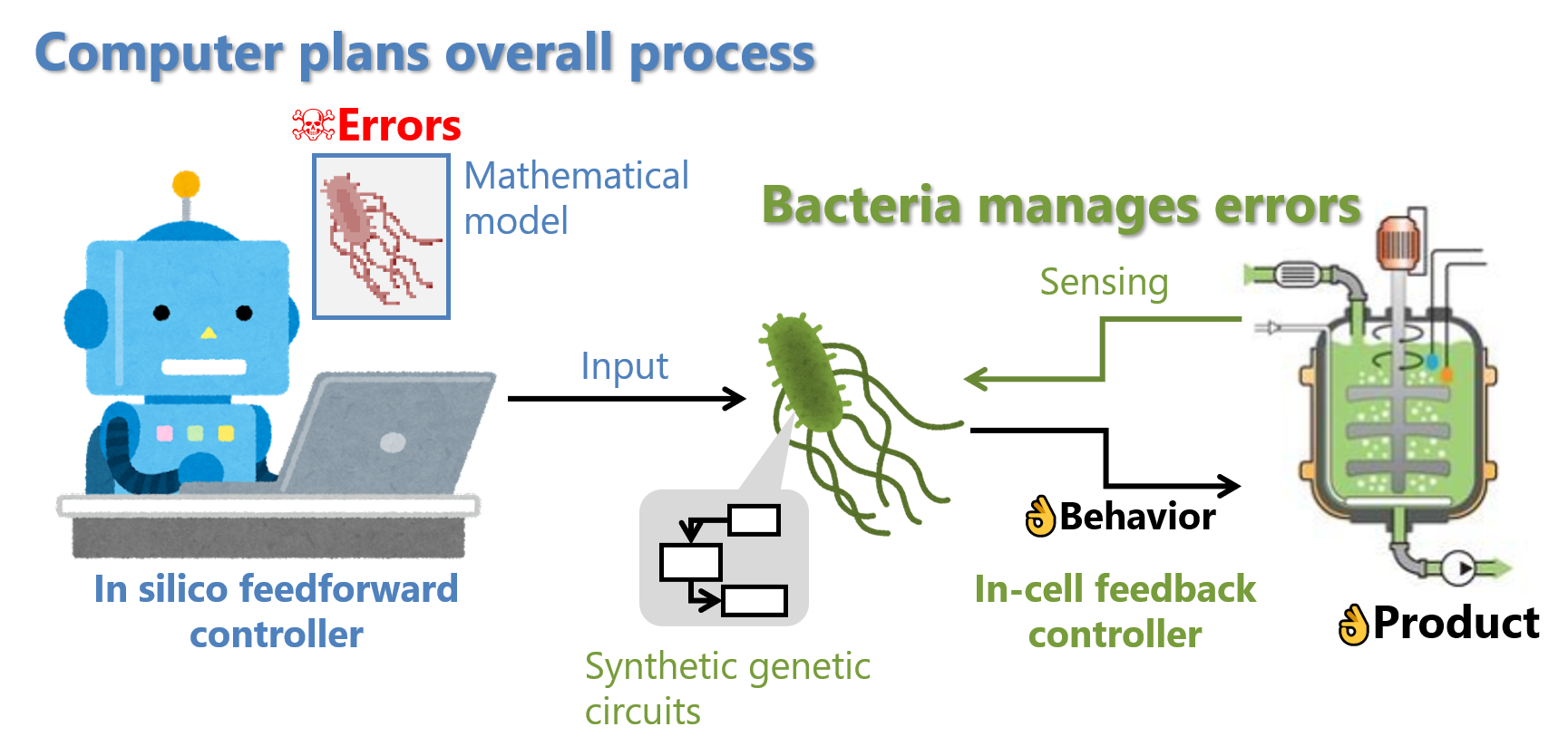

A recent paper published in Scientific Reports demonstrates a proof-of-concept method that effectively addresses the issue of PMM. This paper was made available online on September 4, 2023 and was published in Volume 13 of Scientific Reports. “To address the PMM issue with in silico controllers, we propose a hybrid control strategy that combines a high-level in silico feedforward controller and a low-level in-cell controller,” remarks doctoral student Tomoki Ohkubo from the Graduate School of Science and Technology at Nara Institute of Science and Technology and Senior Assistant Professor Katsuyuki Kunida from Fujita University. The hybrid in silico/in-cell controller (HISICC) proposed in this study combines model-based optimization and the integration of synthetic genetic circuits into cells.

According to the study, PMM can be solved by integrating two types of feedforward and feedback controllers into industrial bioprocesses. The first is aided by a monitoring computer and the second by genetically altered living cells. A computer, for instance, may suggest the optimal temperature and pH for an industrial bioprocess as a feedforward prediction. Meanwhile, in-cell feedback control provides valuable feedback by detecting the actual levels of intracellular nucleic acid, enzymes, and metabolites. It is difficult to determine these parameters using computer-based controllers alone.

To validate their postulate, the research team demonstrates the use of two genetically modified bacterial (Escherichia coli) strains—TA1415 and TA2445—for the optimized production of isopropanol—a versatile cleaning agent, industrial solvent, and chemical intermediate. While TA2445 harbors an in-cell feedback controller, TA1415 does not. More specifically, the in-cell feedback controller in TA2445 comprises a metabolic toggle switch (MTS)—a genetic circuit that exerts control on isopropanol production by responding to a chemical reagent called isopropyl β-d-1-thiogalactopyranoside (IPTG)—and a specialized genetic circuit that allows it to relay real-time feedback on cell density. Although TA1415 has an “MTS,” it is unable to provide any feedback on cell density due to the complete absence of the specialized genetic circuitry.

The team found that the inclusion of the TA2445 strain in the bioproduction results into the optimal regulation of the MTS circuit under the multiple PMM conditions that were intentionally introduced. This enhanced regulation, based on the detection of cell density, prevented the decrease of isopropanol yields due to PMM, resulting in higher yield. In other words, the proposed hybrid control system can efficiently compensate for PMM and robustly maintain the efficiency of microbial material production.

It is a common practice in the field of control to combine a high-level controller that uses a mathematical model with a low-level controller that does not use one. In this study, the authors adopt a novel approach where engineered bacterial cells themselves relay feedback as low-level controllers.

This landmark study has several key implications. The demonstrated method, for instance, could be adapted for the cost-effective and eco-friendly production of chemicals and fuels. Such timely intervention, in tandem with other global initiatives and efforts, could help reverse or mitigate the deadly effects of global warming and climate change in the long term.

“The results show that the in-cell feedback controller in TA2445 effectively compensates for PMM by modifying MTS activation timing. The HISICC system presents a promising solution to the PMM problem in bioprocess engineering, paving the way for more efficient and reliable microbial bioprocess optimization,” explains doctoral student Tomoki Ohkubo and Senior Assistant Prof. Kunida.

Bioprocess engineering focuses on enhancing product yield. It also ensures high output rates and minimal utilization of raw materials. Such precise control is achieved by optimizing the biological behavior of microorganisms employed during the production process. Nevertheless, a process-model mismatch (PMM) emerges when a notable disparity arises between the projected and real production processes. A recent study showcases a proof-of-concept method for effectively addressing the issue of PMM.

One of the primary goals of bioprocess engineering is to increase the yield of the desired material while maintaining high production rates and low raw material utilization. This optimization is usually accomplished by controlling the behavior of microorganisms used in the process and ensuring that their biological capabilities are fully utilized. This control may be computerized (in silico feedforward) or autonomous (in-cell feedback) which predicts the optimization based on inputs received. However, a process-model mismatch (PMM) occurs when there is a discrepancy between the predicted and actual production processes.

A recent paper published in Scientific Reports demonstrates a proof-of-concept method that effectively addresses the issue of PMM. This paper was made available online on September 4, 2023 and was published in Volume 13 of Scientific Reports. “To address the PMM issue with in silico controllers, we propose a hybrid control strategy that combines a high-level in silico feedforward controller and a low-level in-cell controller,” remarks doctoral student Tomoki Ohkubo from the Graduate School of Science and Technology at Nara Institute of Science and Technology and Senior Assistant Professor Katsuyuki Kunida from Fujita University. The hybrid in silico/in-cell controller (HISICC) proposed in this study combines model-based optimization and the integration of synthetic genetic circuits into cells.

According to the study, PMM can be solved by integrating two types of feedforward and feedback controllers into industrial bioprocesses. The first is aided by a monitoring computer and the second by genetically altered living cells. A computer, for instance, may suggest the optimal temperature and pH for an industrial bioprocess as a feedforward prediction. Meanwhile, in-cell feedback control provides valuable feedback by detecting the actual levels of intracellular nucleic acid, enzymes, and metabolites. It is difficult to determine these parameters using computer-based controllers alone.

To validate their postulate, the research team demonstrates the use of two genetically modified bacterial (Escherichia coli) strains—TA1415 and TA2445—for the optimized production of isopropanol—a versatile cleaning agent, industrial solvent, and chemical intermediate. While TA2445 harbors an in-cell feedback controller, TA1415 does not. More specifically, the in-cell feedback controller in TA2445 comprises a metabolic toggle switch (MTS)—a genetic circuit that exerts control on isopropanol production by responding to a chemical reagent called isopropyl β-d-1-thiogalactopyranoside (IPTG)—and a specialized genetic circuit that allows it to relay real-time feedback on cell density. Although TA1415 has an “MTS,” it is unable to provide any feedback on cell density due to the complete absence of the specialized genetic circuitry.

The team found that the inclusion of the TA2445 strain in the bioproduction results into the optimal regulation of the MTS circuit under the multiple PMM conditions that were intentionally introduced. This enhanced regulation, based on the detection of cell density, prevented the decrease of isopropanol yields due to PMM, resulting in higher yield. In other words, the proposed hybrid control system can efficiently compensate for PMM and robustly maintain the efficiency of microbial material production.

It is a common practice in the field of control to combine a high-level controller that uses a mathematical model with a low-level controller that does not use one. In this study, the authors adopt a novel approach where engineered bacterial cells themselves relay feedback as low-level controllers.

This landmark study has several key implications. The demonstrated method, for instance, could be adapted for the cost-effective and eco-friendly production of chemicals and fuels. Such timely intervention, in tandem with other global initiatives and efforts, could help reverse or mitigate the deadly effects of global warming and climate change in the long term.

“The results show that the in-cell feedback controller in TA2445 effectively compensates for PMM by modifying MTS activation timing. The HISICC system presents a promising solution to the PMM problem in bioprocess engineering, paving the way for more efficient and reliable microbial bioprocess optimization,” explains doctoral student Tomoki Ohkubo and Senior Assistant Prof. Kunida.

Hats off to the Japanese researchers for their exemplary contribution to bioprocess optimization, which not only advances the field but also offers promising prospects for carbon footprint reduction!

Image Title: Bioprocess optimization can be improved by addressing the problem of process-model mismatch (PMM)

Image Caption: An in silico model-based controller and an in-cell feedback controller complement each other’s limitations, thus offering an effective solution to the problem of PMM

Image Credit: The Author(s) from Nara Institute of Science and Technology, Kyushu University, and Fujita Health University

License type: Original content

10.1038/s41598-023-40469-y

Image Caption: An in silico model-based controller and an in-cell feedback controller complement each other’s limitations, thus offering an effective solution to the problem of PMM

Image Credit: The Author(s) from Nara Institute of Science and Technology, Kyushu University, and Fujita Health University

License type: Original content

Reference

Title of original paper

A hybrid in silico/in‑cell controller for microbial bioprocesses with process‑model mismatchJournal

Scientific Reports

DOI

10.1038/s41598-023-40469-y

About Dr. Katsuyuki Kunida from Fujita Health University

Dr. Katsuyuki Kunida works as a Lecturer in the Department of Computational Biology at Fujita Health University’s School of Medicine. He obtained his Ph.D. in Medicine from Kyoto University. Dr. Kunida’s research primarily focuses on system-theoretical understanding, prediction and control of cell fate decision making, cell motility, and metabolism related to regenerative medicine and prediction of pathological condition. Dr. Kunida hopes to make significant contributions to preventive medicine by conducting research on precise prediction and control of cell systems. He has won several research awards and he also has more than 20 publications to his credit.